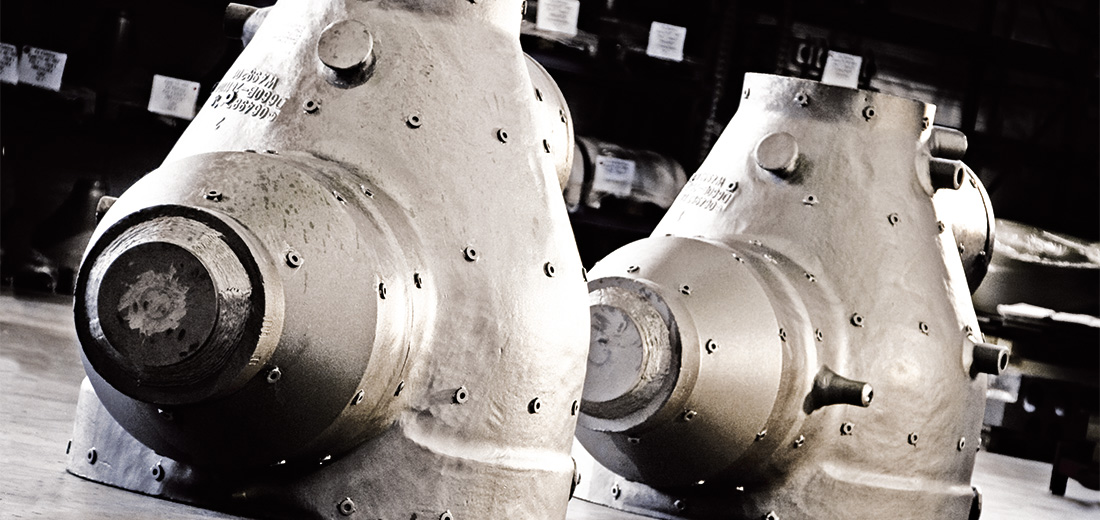

Material Testing

To guarantee highest quality requirements we use non-destructive and destructive testing methods. From simulation to the finished product, the cast parts are subject to constant quality monitoring.

Destructive Material Testing

Samples are taken to check mechanical properties. The following destructive tests are used at SCHMOLZ + BICKENBACH GUSS GmbH: tension test, impact test, metallography, hardness tests according to Brinell, Vickers and Rockwell.

Non-Destructive Material Testing

The methods of non-destructive material testing are used to detect defects on the surface (surface testing) or inside (volume testing) of components.

To guarantee the required quality grade the following non-destructive material testings are used: visual testing, magnetic particle testing, penetrant testing, ultrasonic testing and x-ray testing. Dedicated personnel is carefully trained in accordance with DIN EN ISO 9712 for all test procedures.